Introduction

Establishing a new laboratory calibrating approach isn't any small feat. Whether you are installing a calibration lab for commercial appliance, clinical gadgets, or scientific contraptions, the stakes are prime. Calibration guarantees that your instruments yield good and riskless documents, that's the most important for compliance with trade specifications and policies. In this text, we can discover the key concerns whilst organising a new laboratory calibrating system. From awareness the requisites and settling on incredible gadget to practicing group of workers and guaranteeing pleasant insurance, we can delve into each factor you want to bear in mind for helpful implementation.

Key Considerations When Setting Up a New Laboratory Calibrating System

Setting up a laboratory calibrating technique entails a range of technical and administrative aspects. So enable's wreck down a few of the most central explanations.

1. Understanding Calibration Basics

What is Calibration?

Calibration really refers to the manner of fixing an device's output or signals to believe known values. This is a must have for holding accuracy in measurements.

Why is Calibration Important?

- Ensures security in industries like healthcare. Meets regulatory standards. Enhances operational potency.

2. Compliance with Regulatory Standards

Familiarize Yourself with Relevant Regulations

Different fields have unique regulatory our bodies akin to ISO 17025 for testing and calibration laboratories, FDA rules for clinical contraptions, or ASTM ideas for constituents testing.

How to Ensure Compliance

- Conduct steady audits. Maintain clear documentation. Train team of workers on regulatory necessities.

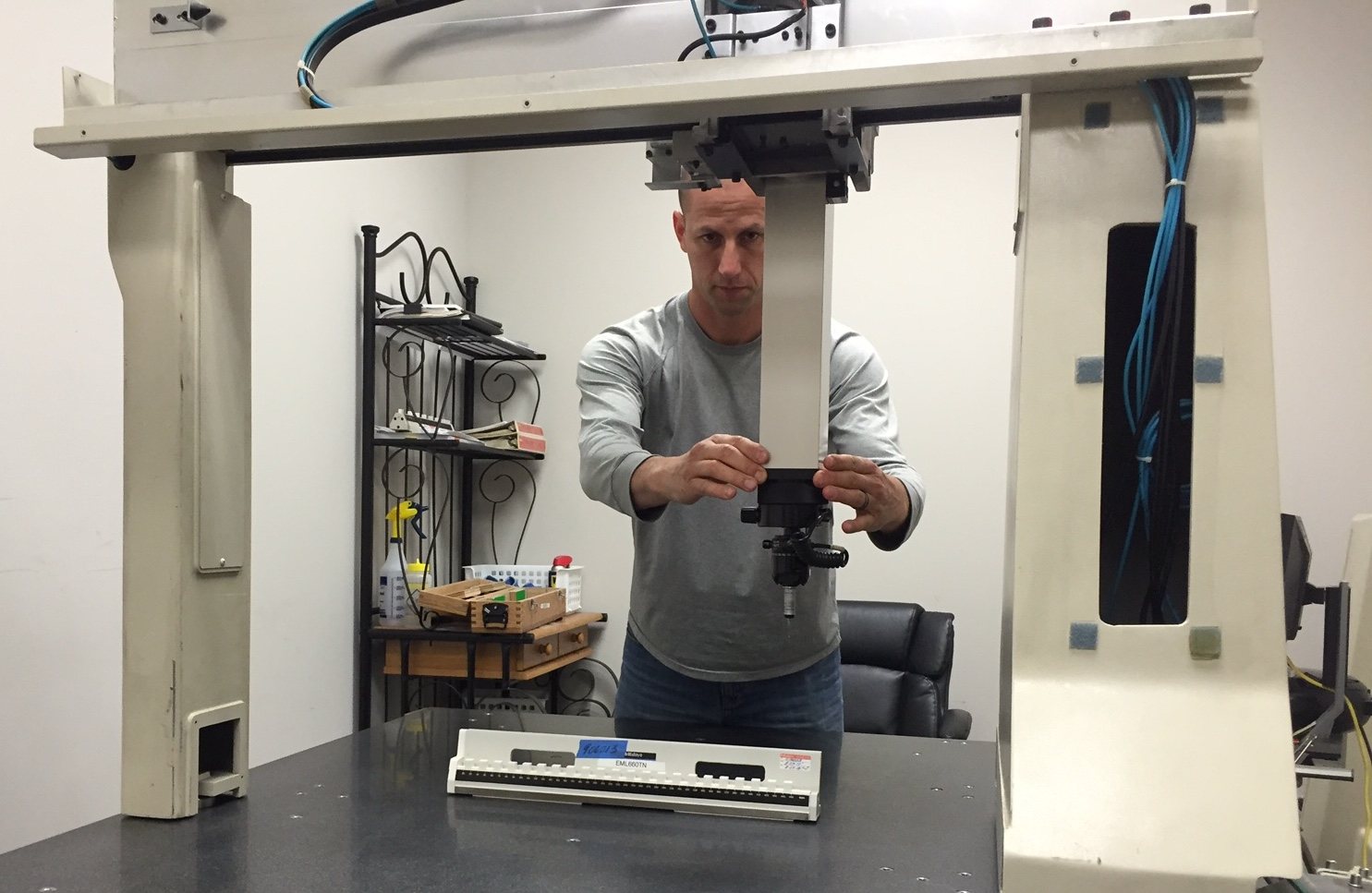

3. Selecting Appropriate Equipment

Types of Calibration Equipment

Choosing the good instruments can greatly effect your calibration consequences. Common models consist of:

- Multimeters Pressure gauges Thermometers

Criteria for Selection

Consider precision, reliability, rate-effectiveness, torque screwdriver calibration services and user-friendliness.

four. Creating a Standard Operating Procedure (SOP)

Importance of SOPs

SOPs furnish step-by way of-step recommendations making sure consistency in calibration methods.

Key Components of an SOP

Purpose of the system. Scope and applicability. Responsibilities of personnel involved.five. Investing in Training Personnel

Why Training Matters

Well-expert employees ascertain that calibration techniques are performed wisely, cutting back dangers of error.

Training Methods

- Workshops Online guides Hands-on exercise periods

6. Implementing Quality Assurance Procedures

What is Quality Assurance?

Quality warranty comes to systematic approaches that determine your calibration amenities meet required specifications normally.

Steps to Implement QA

Establish benchmarks. Regularly overview approaches. Conduct efficiency opinions.7. Choosing Between In-House vs Outsourcing Calibration Services

Pros and Cons of In-House Calibration

Pros:

- Greater handle over approaches. Immediate availability.

Cons:

- Higher preliminary funding. Ongoing repairs charges.

Pros and Cons of Outsourcing Calibration Services

Pros:

- Lower fees to start with. Access to knowledgeable experience.

Cons:

- Less handle over scheduling. Potential conversation things relating to specs.

eight. Designing the Laboratory Layout

Importance of Layout Design

A neatly-deliberate structure complements workflow potency and minimizes infection possibility although engaging in calibrations.

Elements to Consider in Lab Design

Space for device setup. Areas for documentation and info access. Safety zones and emergency exits.9. Data Management Systems

Role of Data Management in Calibration Labs

Effective information control tactics streamline operations because of organizing statistics effectively whereas also serving as a historic reference for audits and inspections.

Features to Look For

User-friendly interface. Robust reporting features. Compliance tracking mechanisms.10. Maintenance Protocols for Equipment

Why Maintenance is Essential?

Regular preservation reduces downtime with the aid of making certain all devices feature safely.

Developing Maintenance Schedules

Create periodic assessments established on producer directions or utilization patterns followed within your lab environment.

eleven. Risk Assessment Procedures

What is Risk Assessment?

Risk evaluate identifies plausible disadvantages related to calibration approaches so you can mitigate them adequately ahead of subject matters get up.

Steps in Conducting Risk Assessment

Identify risks with regards to every calibration task. Evaluate hazards based totally on likelihood and impact severity. Develop mitigation thoughts hence.12. Establishing Traceability Standards

Traceability connects measurements to nationwide or worldwide requirements as a result of documented evidence that demonstrates compliance through the years, significant for credibility within any industry relying on precision measurement.

Frequently Asked Questions (FAQs)

FAQ 1: What is the vital purpose of a laboratory calibrating procedure?

The regularly occurring function is to verify that each one measuring devices provide top readings that adhere to founded principles, for this reason affirming reliability throughout all procedures involving these instruments.

FAQ 2: How in many instances may still I practice calibrations on my system?

Calibration frequency relies upon on a number of reasons such as utilization intensity, precision specifications, and manufacturer techniques; besides the fact that children, maximum industries observe a ordinary rule the place quarterly or biannual tests are conventional exercise.

FAQ 3: Are there exceptional certifications needed for technicians appearing calibrations?

Yes! Technicians can also desire certifications elegant on their vicinity; examples incorporate Certified Calibration Technician (CCT) from ANSI/NCSL or ISO/IEC 17025 accreditation if running inside formal setups.

FAQ 4: Can calibration be done outside lower than discipline conditions?

Yes! Many moveable gadgets permit field calibrations; notwithstanding particular care would have to be taken with regards to environmental causes like temperature alterations influencing measurements at some stage in such tests.

FAQ 5: Is it indispensable to document each calibration approach undertaken?

Absolutely! Comprehensive documentation no longer handiest enables keep compliance but additionally serves as facts for the period of audits or investigations regarding any discrepancies encountered later.

FAQ 6: How do I decide between diversified calibration carrier vendors?

Look at elements akin to their revel in level within your business's niche part, buyer critiques/testimonials from earlier buyers which include skill pricing systems provided via every service issuer ahead of making choices!

Conclusion

Setting up a new laboratory calibrating approach calls for cautious planning throughout a number of domain names—technical information about tools choices alongside strict adherence towards regulatory compliance measures being paramount features all over this travel! By concentrating on key issues when establishing those approaches reported above—together with picking exact tools/gear inclusive of making an investment workers instructions—one could create an productive workflow leading closer to riskless outcomes reaping benefits both inner operations & external stakeholders alike! So cross ahead—take those insights into consideration when designing your subsequent lab setup; it may make the entire difference between mediocrity & excellence!

This article has been crafted fastidiously preserving in brain search engine optimisation satisfactory practices at the same time as proposing crucial insights into setting up effectual laboratory calibrating systems; incorporating the two depth & breadth throughout each and every topic explored herein ensures readers advantage finished abilities at their fingertips—all tailor-made particularly around "Key Considerations When Setting Up A New Laboratory Calibrating System."